Thanks to a large team of automotive engineers, B-Style delivers the best conversion kits on the market. As new vehicles are constantly being introduced and the current kits are continuously being improved, there is always work to be done. That makes engineering at B-Style a fantastic challenge, and we are proud of our people who make it happen.

Table of contents

Designing and innovating

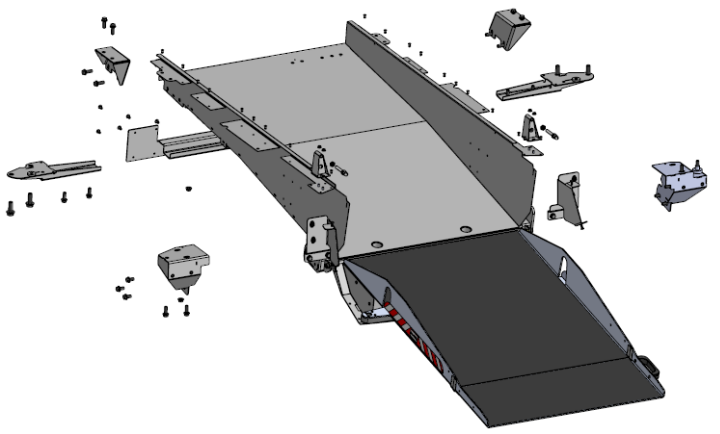

From drawing board to the real world

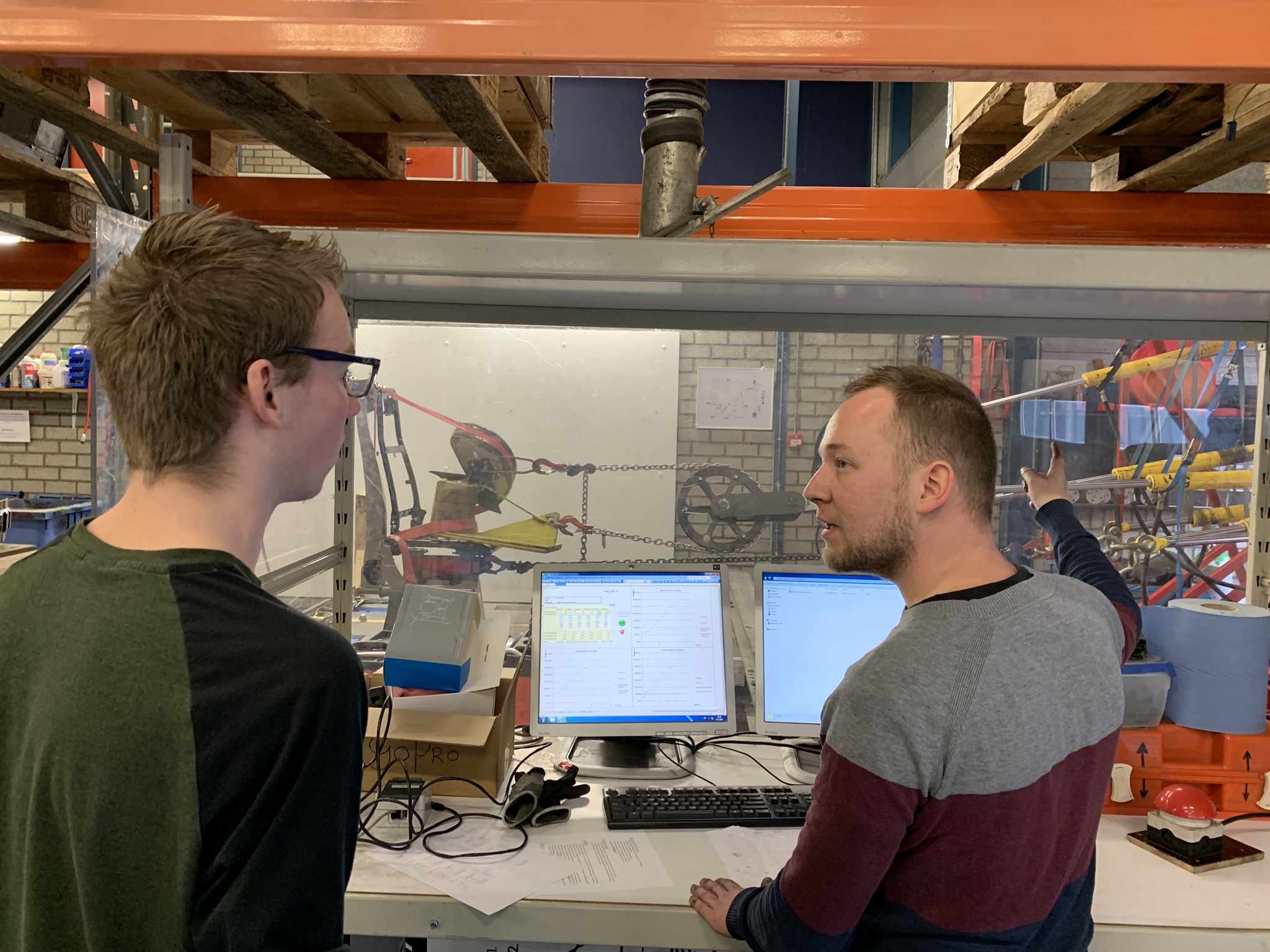

In-house test facilities

Light and strong

Quick installation

Cost-efficient design

Homologation

Ergonomic and user-friendly